Exploring Lallemand's Torula Yeast Specialties: A Remarkable Journey

Embark on a captivating journey into the world of Lallemand's Torula yeast specialties

Torula Yeast

Cyberlindnera jadinii, usually referred as Torula yeast, is a species of yeast commonly used in various industrial applications and as a nutritional supplement. It is a single-celled fungus that belongs to the kingdom Fungi and the phylum Ascomycota.

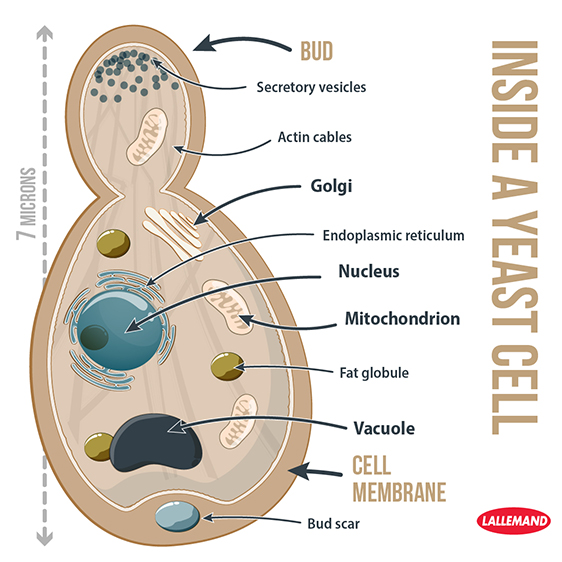

Inside the Cell

The richness of protein content, around 50% of dry cell weight, and amino acid diversity turn its biomass ideal as a source of protein supplement for human and animal consumption.

Torula yeast contains essential amino acids, B-vitamins, minerals (such as potassium, phosphorus, and magnesium), and nucleic acids.

TABLE 1. - AMINO ACID AND VITAMIN CONTENT OF FIVE FOODS IN COMPARISON WITH WHOLE EGG

| Contents | Whole egg | Meat | Milk | Yeast | Peas | Wheat |

|---|---|---|---|---|---|---|

| Essential amino acids | ||||||

| Arginine | 100 | +20 | -33 | -27 | +39 | -30 |

| Histidine | 100 | -10 | +20 | +13 | -43 | -5 |

| Isoleucine | 100 | -21 | -22 | -7 | -49 | -55 |

| Leucine | 100 | -13 | +23 | -17 | -30 | -26 |

| Lysine | 100 | +6 | +4 | -14 | -30 | -65 |

| Methionine | 100 | -22 | -20 | -71 | -76 | -76 |

| Phenylalanine | 100 | -27 | -16 | -36 | -24 | -40 |

| Threonine | 100 | +9 | -6 | +2 | -20 | -39 |

| Valine | 100 | -21 | -10 | -9 | -45 | -44 |

| Vitamins | ||||||

| B1, thiamine | 100 | +36 | -73 | +1540 | +446 | +58 |

| B2, riboflavin | 100 | +3 | -39 | +1580 | -21 | -25 |

| Niacin | 100 | 462 | -62 | +1720 | +75 | +588 |

| B6, pyrodoxine | 100 | -30 | -90 | +60 | -93 | -72 |

| Pantothenic acid | 100 | +36 | -75 | -64 | ||

| H, biotin | 100 | -96 | -97 | +100 | -97 | -100 |

In Table 1 the essential amino acids in whole egg, taken as 100, are compared with the contents of other foods. Some vitamins are included in the same manner. Whole egg protein is the best – but also the most expensive protein. The Table shows that all proteins, whether of plant or animal origin, differ from whole egg in having either a higher or a lower content of the various amino acids and vitamins. Milk and meat approach nearest to whole egg while peas differ most. As regards protein alone, the biological value of yeast equals that of the best vegetable protein.

Source: FAO Based on a paper presented at the sixth meeting of the FAO Technical Parcel on Wood Chemistry, Stockholm, 27-28 July, 1953 “Food and feed yeast in Germany”

A Glimpse into the Past

The benefits of yeast have been recognized since ancient times. However, the understanding of yeast as a valuable source of food for both humans and animals is a relatively recent discovery.

The world conflicts of the 20th century encouraged European extensive research in this area, as the failure of imports from overseas due to the wars led many countries to face a severe protein deficiency. During the First World War, Germany encountered a significant shortage of food and fodder. In response, plans were devised to produce a substantial amount of feeding yeast by utilizing molasses, supplemented with ammonium salts as a nitrogen source. However, this strategy faced a setback when the supply of molasses eventually dwindled, leading to the closure of the newly constructed yeast plants.

During the 1930s, Professor Fink put forth a proposition suggesting the utilization of sugars found in sulphite pulp waste liquor or those generated by the wood processing industry as an alternative to molasses, an agricultural product. However, this alternative proved to be expensive. Additionally, the larger pulp mills in Scandinavia and Germany already possessed alcohol plants, making it difficult to obtain significant quantities of softwood waste liquor.

Nonetheless, Professor Fink made a significant discovery that Torula yeast could thrive on both pentose and hexose sugars. This finding indicated that hardwood waste liquors, produced by the wood processing industry, could also serve as a suitable substrate. In Germany, there was a growing amount of beech waste liquor available, yet no practical applications had been identified for it at that time.

The advent of the Waldhof yeast propagator, capable of producing yeast cream in continuous batches, significantly bolstered yeast production.

Following 1943, these production methods were exported to Switzerland and subsequently to the United States at the end of WWII. The US Department of Agriculture, supported by the University of Wisconsin played a crucial role in supporting the expansion of the emerging utilization of the “beefsteak yeast,” (Torula yeast) which had the ability to thrive on wood processing by-products.

By the late 1960s, food companies had already started incorporating Torula yeast into a range of products intended for human consumption. These applications included milk flavoring products as well as savory spreads, showcasing the versatility and widespread use of Torula yeast in the food industry.

Lallemand's Journey to Leadership in Torula Yeast Production

Lallemand Bio-Ingredients specializes in producing a complete range of natural inactive whole-cell yeast, yeast autolysates, and yeast extracts for applications and product developments in savory, health (functional foods and supplements), and fermentation media markets.

Initially formed in 1987 to develop value-added products while optimizing the processing of yeast biomasses that seasonal extra-capacity plants made available, Lallemand Bio-Ingredients developed in time a strong know-how and experience in yeast-based, fermented ingredients.

In 2009 Lallemand announced the acquisition of Lake States Yeast Division from the Wausau Paper Group: Lake States production began in 1948 in Rhinelander, Wisconsin. For over 50 years the site has been a leader in the development and commercialization of inactive dried torula yeast. With a focus on innovation and utilizing cutting-edge technologies, Lallemand successfully optimized the production process of torula yeast. The original production method, which relied on paper-mill byproducts, transitioned to molasses and dextrose.

In 2019 Lallemand acquired Ohly’s Torula yeast production site in Hutchinson, Minnesota.

Through strategic collaborations, partnerships, and a customer-centric approach, Lallemand is building a strong reputation for delivering top-quality Torula yeast products and tailored solutions to meet the diverse needs of its customers worldwide, solidifying the company’s position as a frontrunner in the industry.

Product Portfolio

By leveraging the unique properties of Torula yeast and the expertise in strain selection, Lallemand Bio Ingredients provides a diverse array of yeast specialties that align with the diverse needs of the food industry. Presently, Lallemand produces Torula yeast and Torula autolyzed yeast in three primary locations.

The renowned Toravita® brand is manufactured in Hutchinson, MN, United States, while Lake States® remains in production at the Rhinelander facility, WI. Additionally, Lake States® Type E is produced in Estonia (NGP Verified). In 2023, an exciting development occurred as the NGP Verified item Lake States Type E produced in Europe was complemented by its corresponding NGP verified item produced in Rhinelander, Wisconsin and named Lake States® Type N. The Bakon® brand offers traditionally smoked torula yeast specialties.

Product Highlights

Primary grown, torula-based dried whole cell or autolyzed yeast, produced by a unique process, delivering specific functionality and flavor notes to different food applications.

| THE CLASSICS | |

|---|---|

| Toravita® 001 |

Toravita® 001High quality primary grown, dried inactive yeast has applications in a wide variety of food systems where high quality and a uniform mild flavor are required. It’s profile is mild, dairy-like. It is often used in seasoning mixes as carrier for spices, oleoresins, and smoke flavorings. Used at 0.3-0.9% in the finished product, it enhances meat and poultry flavors, batters and bakery items. Suitable for low and reduced fat systems. |

| Toravita® 024 |

Toravita® 024Primary grown Torula yeast produced through continuous fermentation. It is a convenient flavor carrier, with mild savory flavor and texture enhancing properties due to its water-binding abilities. Low in sodium, it is suitable for use in various food formulations. |

| THE UMAMI ESSENCE | |

|---|---|

| Toravita® 054 |

Toravita® 054Primary grown autolyzed yeast with umami flavor properties thanks to the high content of natural nucleotides and other natural flavor potentiators. It can be used to round-off and accentuate the mouthfeel of several food applications and it helps to balance sodium-reduced formulations. |

| DEDICATED TO SODIUM REDUCTION | |

|---|---|

| Toravita® 028 SD |

Toravita® 028 SDSpecial low sodium yeast autolysate that adds “salty” flavor without adding substantial sodium. The co-processed combination of ammonium chloride and the yeast autolysate is significantly less bitter than ammonium chloride alone. |

| Toravita® 029 SD |

Toravita® 029 SDUnique, low sodium, yeast autolysate that adds “salty” flavor without adding substantial sodium. This co-processed combination of potassium chloride and a yeast autolysate is significantly less bitter than potassium chloride alone. It also provides the flavor enhancement characteristics common to all of our autolyzed yeast products. |

| MEAT PROCESSOR’S FAVORITES | |

|---|---|

| Toravita® 030 |

Toravita® 030Low sodium autolyzed yeast conceived to enhance flavors in meat products, especially emulsions. It provides meat processors an effective flavoring ingredient. A similar product is also available without the oil coating, named Toravita® 032. |

| Toravita® 033 |

Toravita® 033A very specific yeast autolysate designed to enhance flavors in emulsified meat products. The high-water binding capacity suits formulations to replace phosphates in food matrix. |

| THE FLAVOR MODULATORS | |

|---|---|

| Toravita® 300-301 |

Toravita® 300-301Multi-functional food ingredient derived from primary grown inactive yeast, effective as flavor maskers, both in sweet and savory application. They are particularly effective in plant-based formulations to decrease the impact of undesired “green” notes, typical of the vegetable proteins (grassy, hay, bitterness, etc). In Europe and North America can be declared on the ingredient list as “natural flavors”*. * Local food regulations should always be consulted with respect to specific applications and necessary declarations. Legislation may vary from country to country |

| Toravita® 600-604 |

Toravita® 600-604Toravita® 600 Is a multi-functional food ingredient derived from primary grown inactive yeast. It aims to improve the flavor of fat-reduced, pourable salad dressing by reducing the “acid bite” of vinegar. The addition of Toravita® 600 to any salad dressing system produces a smoother, more balanced flavor. In plant-based application may help as well to reduce the undesirable off-flavors typical of plant-proteins Toravita® 604 s a primary grown inactive torula yeast. It plays a significant role in reducing the acid bite in cultured dairy products and creamy salad dressings. Its addition results in a smoother and more balanced flavor release. |

Toravita® primary grown inactive yeast goes through a traditional smoking process to produce Bakon®, smoked inactive torula yeast.

| Bakon | |

|---|---|

| SFBN and HFBN |

SFBN and HFBNCharacterized by a unique smoked profile, SFBN is milder than HFBN. They contribute the typical BBQ flavor notes. They also mask off-flavors associated with soy. Those ingredients are suitable for meat applications, soups, stews, snack foods, dry seasoning mixes, and vegan and vegetarian meals. The standard dosage range is from 0.5 to 3.0% in the finished product. |

Primary grown, dried whole cell torula inactive yeast. It is a specialty product range with the unique ability of delivering superb flavor carrier properties in different food applications, with distinctive savory notes and superior texture enhancement.

A Distinctive Savory Profile

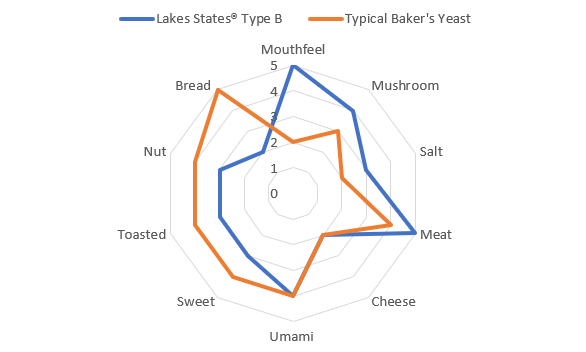

The selected substrates and the metabolism of Torula yeast compared to Saccharomyces cerevisiae, impart a unique to the Lake States® portfolio a unique meaty & savory profile, interesting for snacks and spice blends, meat products as well as meat-free alternatives, savory spreads, and many other food preparations.

| Lake States | |

|---|---|

| TYPE B |

TYPE BProduced in the USA is the iconic example of the Lake States® brand. Primary grown dried whole cell can be used to improve the overall flavor with its umami, savory and meaty notes. Used at 0.5-1% for its flavor contribution, will modify the texture in emulsions and spreads at 1 – 3%. |

| TYPE L |

TYPE LPrimary grown dried whole cell, with a lighter flavor and color compared to type B. It is an outstanding flavor carrier, with a savory profile and texture enhancing properties |

TYPE N

|

TYPE NNon-GMO Project Verified (NGP), it is produced in the USA. Primary grown dried whole cell, is an outstanding flavor carrier, with distinctive savory flavors and texture enhancing properties.

|

Learn more about the Non-GMO Project

More products are available upon request.

We will be happy to support you in the selection of the right product to suit your needs.